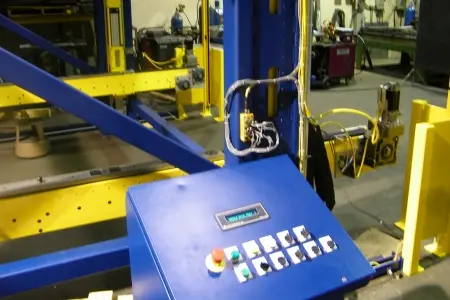

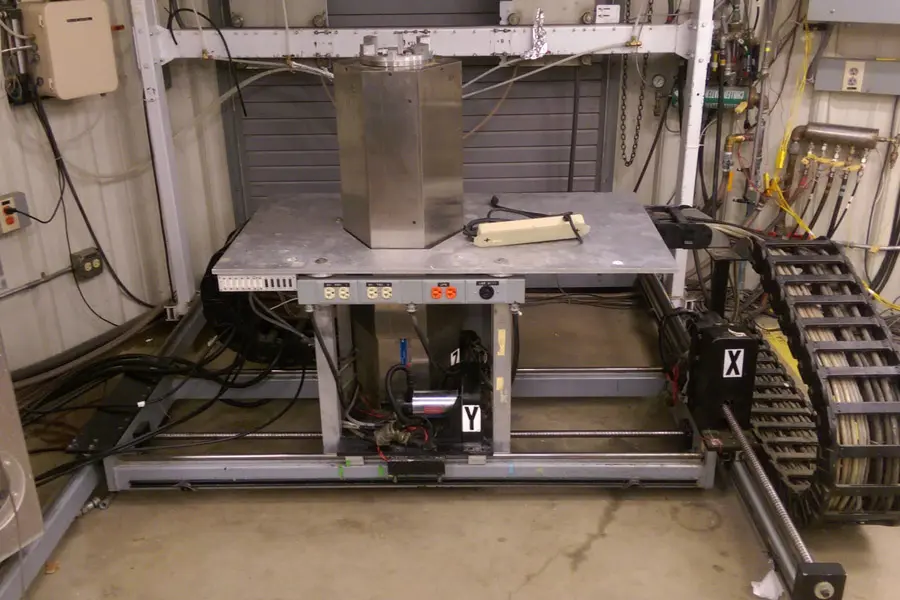

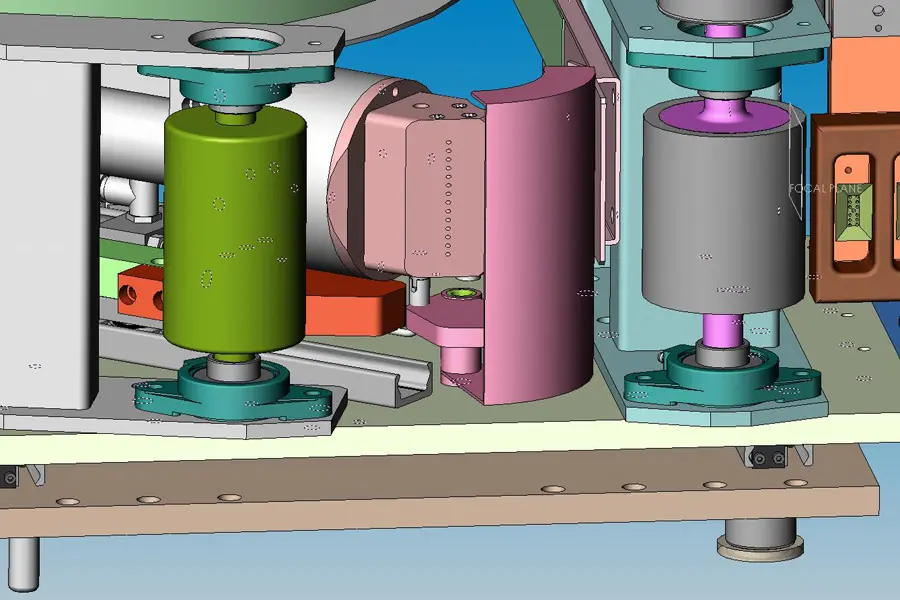

Modern industry demands fast handling and low failure rates. Shipping bad product results in wasted time and money, as well as a bad customer experience. In-process inspection, whether via vision, laser, or other sensors tailored to the application, is the best way to detect and correct or remove bad product before it leaves your facility. Genesis can help you integrate inspection capabilities into your existing system or create a work cell specifically tailored to inspect your parts. Since every part and process is unique, inspection stations should also be unique, to get you as much actionable data as possible. This data should be provided as quickly as possible, without lowering throughput. Genesis can additionally provide this data to other systems, such as Data Acquisition Units, Matlab, Industrial Controllers, Web Portals, SQL, or even to a manual inspector, so that you can have your data where you need it, when you need it.

Modern industry demands fast handling and low failure rates. Shipping bad product results in wasted time and money, as well as a bad customer experience. In-process inspection, whether via vision, laser, or other sensors tailored to the application, is the best way to detect and correct or remove bad product before it leaves your facility. Genesis can help you integrate inspection capabilities into your existing system or create a work cell specifically tailored to inspect your parts. Since every part and process is unique, inspection stations should also be unique, to get you as much actionable data as possible. This data should be provided as quickly as possible, without lowering throughput. Genesis can additionally provide this data to other systems, such as Data Acquisition Units, Matlab, Industrial Controllers, Web Portals, SQL, or even to a manual inspector, so that you can have your data where you need it, when you need it.